Reduction of Environmental Burdens and Risks from Business Activities

Environment

Utilization of Renewable Energy

The DOWA group is aggressively promoting use of renewable energy that has less environmental burden as well as energy saving and conversion of fuel as part of global warming measures. Renewable energy is produced from natural power and by effective use of disposed energy. This enables reduction of fossil fuel usage and CO2 emission.

Power generation from wastes

Power generation from wastes effectively utilizes wasted heat. Heat generated when wastes are incinerated is used to generate steam and in turn steam run turbines to generate electricity. It is an excellent system to reduce consumption of fossil fuel such as oil, resulting in reduction of CO2 emission. Four business entities in Japan and one outside Japan are engaged in power generation in the DOWA group. Amount of electricity generated from wasted heat increased by approximately 20%, amounting 74.3GWh compared to previous year in 2013.

Hydraulic power generation

This utilizes water flow to generate electricity, and is purely a domestic energy with less environmental burden. Kosaka Smelting and Refining started power generation in 1879 to produce gold, silver and copper. Kosaka has six hydraulic power plants in Akita Prefecture now. Power generated in 2013 increased by approximately 13%, amounting to 67.8GWh compared to previous year. These are major power sources of smelting business of DOWA.

Solar power generation

Four companies of DOWA implemented the solar power generation system in Japan. The total power generated by these four companies is approximately 300MWh in 2013. Despite the fact output from the solar power generation system is dependent on weather conditions, output can be visualized in a display, thus, helping to raise employees' awareness of energy-saving and to enlighten visitors on global warming and energy issues.

Biodiesel

Biodiesel Okayama recovers used cooking oil from homes, convenient stores, restaurants and food manufacturing plants and produces BDF (Biodiesel fuel) jointly with Okayama City. The fuel is used for garbage trucks and buses of Okayama City and trucks and forklifts within the premises of DOWA companies as alternative fuel for diesel oil, contributing to CO2 reduction. The quality certification system of the Zenkoku Biodiesel Nenryo Suishin Kyogikai (National Biodiesel Fuel Promotion Council) recognized that the BDF of Biodiesel Okayama is of top quality.

Evaluation from Society

"Okayama Environmental Grand Prize" Awarded to Biodiesel Okayama's Initiative Biodiesel Okayama received the Okayama Environmental Grand Prize for the field of promoting to build resource-recycling society in October 2013. The reason of the award is as follows: Its initiative to convert used cooking oil to biodiesel fuel contributed to building resource-recycling society; and its active environmental education program helped to enlighten people on importance and mechanism of recycling. |

Promoting Resource-Recycling

The DOWA group is committed to contributing to build a sustainable society by restricting consumption of natural resources and promoting recycling of used resources.

INPUT

INPUT

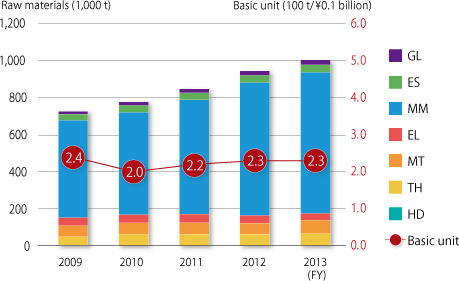

<Raw material>

The amount of raw materials used in 2013 is 1,006,000 t, increase by 6% compared to previous year.

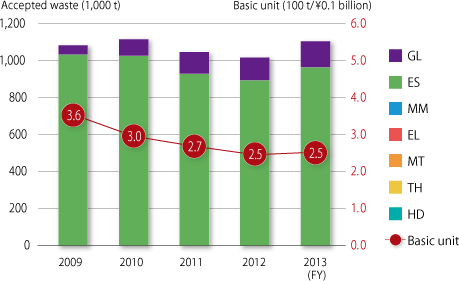

<Accepted wastes>

The amount of accepted wastes in 2013 is 1,122,000 t, an increase of 9% compared to previous year. This is attributable to increase of accepted wastes of Eco-System Chiba and Eco-System Hanaoka.

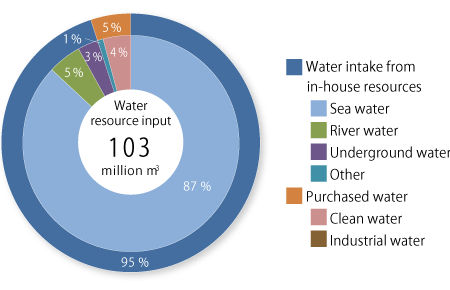

<Water resource>

Water resource input in 2013 is 103 million m3, decrease by 2% compared to previous year. The top water usage is cooling water, accounting for approximately 87% of the entire water usage. Sea water is used for cooling. Fresh water usage accounts for approximately 13 % of the entire water resource input. Fresh water is used for production and clean water.

Resource Saving and Recycling Efforts in 2013

|

Reduction of usage of coke by 7% |

|

Reduction of purchased raw materials by approximately 16% |

|

Reduction of raw material for tin by approximately 2% |

|

Increase of recycled materials by 1,837kg |

OUTPUT

OUTPUT

<Products>

Products manufactured in 2013 is 569,000 t, 4% increase compared to previous year. It is attributable to increased shipment of zinc and processed zinc products.

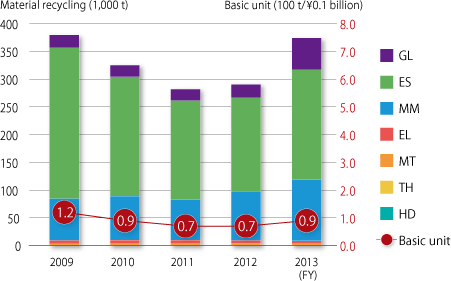

<Material recycling>

The amount of material recycling in 2013 is 374,000 t, a dramatic increase by 29% compared to previous year. The material recycled within the DOWA group accounts for 156,000 t, while that outside the group accounts for 218,000 t. It is mainly due to the increased soil recycling and recycling of used oil.

Our policies to reduce packaging materials in 2013

Our policies to reduce packaging materials in 2013

We optimize packaging method through wider use of large containers in order to reduce the use of packaging materials.

We optimize packaging method through wider use of large containers in order to reduce the use of packaging materials. We make every effort to promote reusing of containers and packaging materials by utilizing used flexible containers and returnable containers.

We make every effort to promote reusing of containers and packaging materials by utilizing used flexible containers and returnable containers. We coordinate with our suppliers in order to collect containers smoothly.

We coordinate with our suppliers in order to collect containers smoothly.

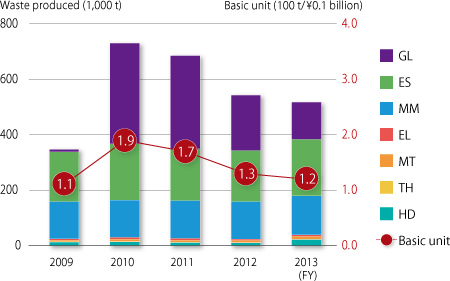

<Waste>

The amount of wastes produced in 2013 is 517,000 t, 5% decrease from previous year.

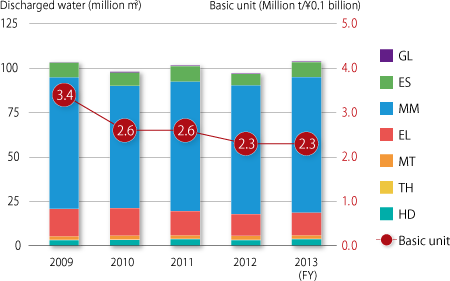

<Discharged water>

Total discharged water in 2013 is 104,000 t, 7% increase from previous year. It is caused by the increase of discharged rain water as a result of increased rainfall. It is also attributable to the increased use of sea water for cooling in connection to the increase zinc production.

Air and Water Pollution Loads

Air and water pollution loads of the DOWA group are greatly influenced by the composition of waste accepted by our Environmental & Recycling business. Each of our business establishments is committed to reducing these loads by enhancing their management system and setting forth its own standard that is stricter than governmental regulations.

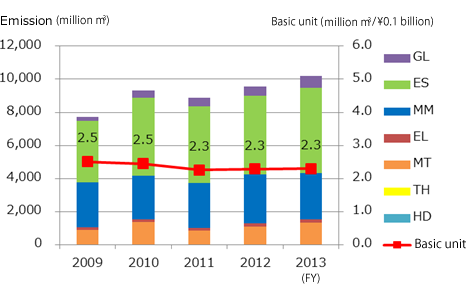

Exhaust gases

Exhaust gases

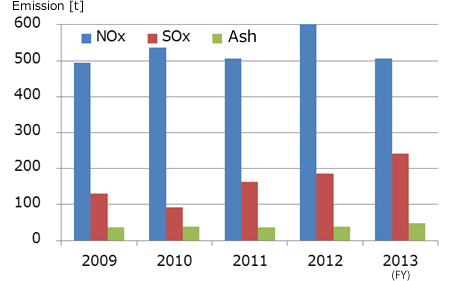

Emission of exhaust gases in 2013 was 10,214 million m3 (9,492 million m3 in Japan and 723 million m3 other countries) and the exhaust gas emission in Japan increased by 5% compared to the previous year. Emission of nitrogen oxide (NOx) in Japan increased by 16% and sulfur oxide (SOx) and fly ash decreased by 30% and 25% respectively. The increase of emission of those gases was based on change of the amount of waste acceptance, and composition.

<Changes of Emission of Exhaust Gases>

<Changes of Air Emission per Substance>

Water Quality

Water Quality

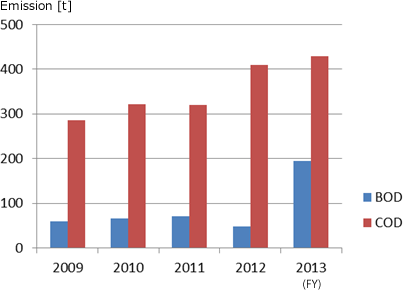

Emission of BOD (biochemical oxygen demand) and COD (chemical oxygen demand) in Japan increased by 13% and 4% compared to the previous year. This was mainly due to the increased operation.

<Changes of Waste Water Discharge into Water Area per Substance>

Quantity of Disposed and Transferred Chemical Substances

We endeavor to reduce disposal of substances targeted for the PRTR (Pollutant Release and Transfer Register) law in each of our plant, based on the law concerning understanding the discharged amount of special chemical substances into the environment and promoting improvement of their management (PRTR law).

Measures for Reduction

Measures for Reduction

Recovery and reuse of chemical agents used in processes

Recovery and reuse of chemical agents used in processes Development of products that substitute for or that do not use hazardous substances

Development of products that substitute for or that do not use hazardous substances

Unit: (g-TEQ for Dioxins)

| Cabinet order No. | Name of Class I chemical substances | Discharged amount | Transferred amount | ||||

|---|---|---|---|---|---|---|---|

| Atmosphere | Water area | Soil | Landfill within our own property | Sewage system | Outside of each business | ||

| 1 | Water-soluble compounds of zinc | - | 6.0 | - | - | - | - |

| 31 | Antimony and its compounds | 0.04 | 0.3 | - | 140 | - | - |

| 44 | Indium and its compounds | - | - | - | - | - | 7.0 |

| 53 | Ethyl benzene | 0.004 | - | - | - | - | - |

| 71 | ferric chloride | - | 0.005 | - | - | - | 5.5 |

| 72 | Chlorinated paraffin (C=10-13) | - | - | - | - | - | - |

| 75 | Cadmium and its compounds | 0.02 | 0.09 | - | 52 | - | 33.1 |

| 80 | Xylene | 0.004 | - | - | - | - | - |

| 82 | Silver and its water-soluble compounds | 0.01 | 0.004 | - | 5.8 | - | - |

| 87 | Chrome and trivalent chrome compounds | - | 0.07 | - | 110 | - | 2.0 |

| 132 | Cobalt and its compounds | - | - | - | - | - | 1.3 |

| 144 | Inorganic cyanogen compounds (excluding complex salt and cyanic acid) | - | - | - | - | - | 0.003 |

| 237 | mercury and its compounds | - | - | - | 0.3 | - | - |

| 242 | Selenium and its compounds | 0.01 | 0.2 | - | 6.2 | - | - |

| 243 | Dioxins | 0.06 | 0.0005 | - | - | - | 15.0 |

| 258 | 1,3,5,7-tetraazatricyclo[3.3.1.13.7] decane; hexamethylenetetramine |

- | 0.05 | - | - | - | 1,529.7 |

| 272 | Water-soluble salt of copper (excluding complex salts) | - | 1.2 | - | - | - | 7.5 |

| 304 | Lead | 0.34 | 0.07 | - | 1400 | - | 42.0 |

| 305 | Lead compounds | - | - | - | - | - | 1,605.5 |

| 308 | Nickel | - | 0.007 | - | - | - | - |

| 309 | Nickel compounds | - | 1.2 | - | - | - | 0.8 |

| 332 | Arsenic and its inorganic compounds | 0.07 | 0.07 | - | 750 | - | 355.2 |

| 333 | Hydrazine | - | - | - | - | - | 1.9 |

| 374 | Hydrogen fluoride and its water-soluble salt | 0.26 | 36.0 | - | - | - | 3.4 |

| 405 | Boron compounds | - | 9.1 | - | - | - | 1.2 |

| 411 | Formaldehyde | - | 0.2 | - | - | - | - |

| 412 | Manganese and its compounds | - | 6.3 | - | - | - | 928.3 |

| 438 | Methylnaphthalene | 0.04 | - | - | - | - | - |

Expanding into Eco-friendly Products

and Renewable Energy Fields

The FIT (Feed in Tariff) system started in Japan in 2012 for the purpose of expanding the use of renewable energy including solar power, wind power or biomass. This system has been steadily propelled implementation of solar and wind power generation.

The DOWA group is committed to spreading renewable energy by providing products and technologies for various equipment in the field.

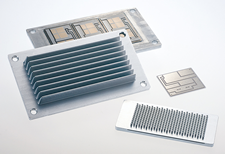

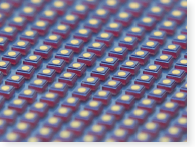

Metal Ceramic Printed Circuit Board (PCB) by DOWA

Metal Ceramic Printed Circuit Board (PCB) by DOWA

DOWA̓s metal ceramic PCB circuit board is an insulating substrate for semiconductor devices that effectively control electricity. Our product is reliable with excellent insulation and heat dissipation properties and used widely for pressure resistant power modules used in industrial machinery. Power modules used for wind or solar power generation require better performance. As such, we endeavor to mass-produce products with high pressure resistance and reliability such as substrates integrated with aluminum bases to respond to expanding demands.

DOWA's Eco Products Contributing to Environmental and Energy Fields

We are trying to develop materials that contribute to reduction of environmental burden and improve their technologies across the entire supply chain so that our client companies manufacture products that use our materials; and thereby realizing energy saving, resource saving and hazardous substance-free society.

<Nitride-based HEMT epitaxial substrates>

Material for power semiconductor devices

| Applications | Power supply of home electric appliance, server and hybrid car |

|---|---|

| Environmental performance | Energy saving, electric resistance lower than silicon-based substrates and power loss control of one third. |

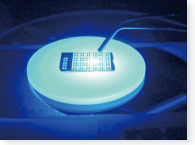

<Deep ultraviolet LED>

LED that can output deep ultraviolet of 350 nm or less

| Applications | Resin hardening, adhesion, drying, medical treatment, analysis, photocatalyst or water purification |

|---|---|

| Environmental performance | Energy saving, high efficiency, long life cycle, reduction of hazardous substances (lead-free) and wavelength (300nm or less) to realize disinfection and sterilization of water or material surface efficiently |

<MR (laminate) LED>

High output infra-red LED chips with a bonding technology that bonds a highly functionalized epitaxial thin film substrate consisting of several tens of crystalline layers in a nanometer order to the substrate with a metal reflection part.

| Applications | Proximity sensors for smart phones |

|---|---|

| Environmental performance | Energy saving/less power consumption by high output |

Evaluation from Society

The Harunari Inoue Award for

|