DOWA Metals & Mining conducts refining and smelting, which is the core focus of the DOWA group. Metals & Mining has established a recycling, refining and smelting complex consisting of a network of several refining and smelting plants, based on our long cultivated technologies for mining, smelting and refining. Metals & Mining contributes to building a resource-recycling society through recycling, refining and smelting of twenty-some metals recovered from a wide variety of raw materials.

Business Fields

| Precious metal and copper business |

Rare metal business | Zinc business |

Main Products and Services

Gold, silver, copper, zinc, zinc alloy, lead, platinum, palladium, indium, gallium, germanium, tin, antimony, crude nickel sulfate, bismuth, tellurium, sulfate, etc.

<Introduction of one of the Main Plants of DOWA Metals and Mining>

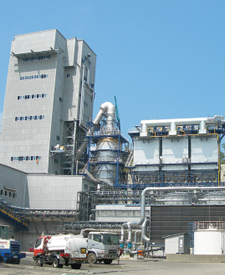

A World-leading Combined Recycling, Refining and Smelting Plant that Handles Diversified Raw Materials

We have established an operation system with concerted efforts to tackle with an extensive transformation to shift to a refining and smelting process focusing on recycling materials.

Address : 60-1 Otarube, Kosakakouzan, Kosaka-machi, Kazuno-gun, Akita 017-0202

Employees : 314 (As of March 31, 2014)

Advanced Combined Recycling, Refining and Smelting Process

Kosaka Refining and Smelting changed its method from a blast furnace and flash smelter method to the TSL (Top Submerged Lance) furnace method in 2008. It was an extensive transformation that had not been accomplished before in Japan or in anywhere else in the world. Kosaka not only changed the process but also the materials from mined minerals to mainly recycled materials. The DOWA group overcame various problems with concerted efforts and was able to establish a safe operation. To be able to handle a wide variety of materials including recycled ones, Kosaka started to collect crude nickel sulfate and tin in the fiscal year of 2011 and is now increasing the number of recovered metals. In 2013, Kosaka succeeded in increasing production of silver through further improvement of silver refining and smelting process.

Conflict-free Mineral Refining and Smelting Plant

Kosaka Refining and Smelting carries out its social responsibility to a full extent as a company to supply non-ferrous metals at the upper stream of the supply chain. Kosaka was the first Japanese company that obtained the CFS (Conflict Free Smelter) certificate from EICC/GeSI in 2012 and obtained the renewed certificate in 2013. Kosaka is committed to further conducting risk management of conflict minerals, in cooperation with suppliers of mineral and recycled materials, not only for its direct customers we supply gold bullion but also for end-user companies of gold at the lower end of the supply chain.

Takehiro Muramatsu, Precious Metal Division

Employees on our production site have been making concerted efforts to achieve improvements such as productivity of the material processing furnaces in the precious metal plants to increase silver production. As a result, material processing throughput increased 1.5 times, contributing to our being the top silver producer in Japan.

Although there are still many challenges in connection with shifting to recycled materials including diversification of the composition of raw materials, we are steadily working to overcome the problems.

Tetsuro Tokumoto, Production Control Division

Kosaka Smelting and Refining has transformed its usage of raw materials from mined minerals to recycled materials in connection with environment changes to produce non-ferrous metal bullion. To respond now to these changes and carry out our responsibilities appropriate to the times, Kosaka obtained the CFS certificate to be a responsible manufacturer.

We will continue to respond to environmental and social needs agilely and flexibly to make reliable products.

Donation of Locomotives and Station Building

of Old Kosaka Railways to Kosaka Town

Kosaka Railways used to be the main means of transportation of minerals and sulfuric acid when Kosaka Smelting and Refining used the flash smelter. It ceased the operation in 2009. Kosaka assigned diesel locomotives, old station building and railway site of Kosaka Railways free of charge to Kosaka town in March 2014, in response to the request from local communities to make use of locomotives and Russel snowplows as tourism resources. The town will use these resources to show its industrial heritage and there are plans to build a railway theme park focusing on customer experiences of operating locomotives themselves as well as exhibitions.