Reduction of Environmental Burdens and Risks from Business Activities

Environment

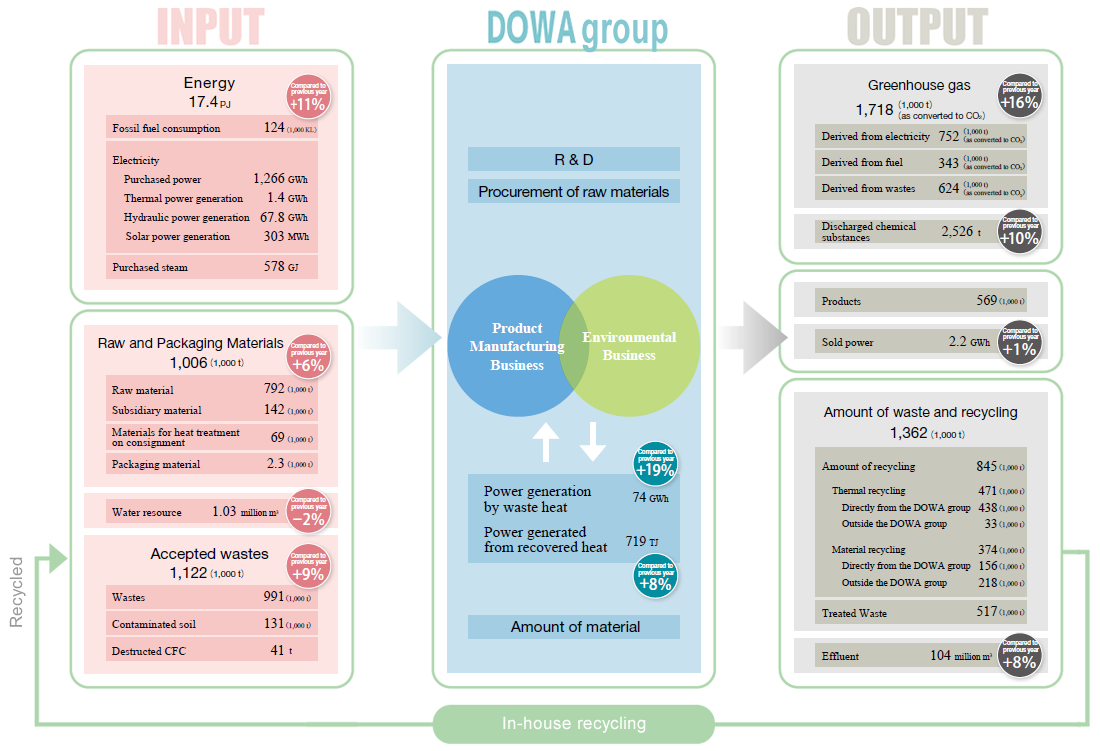

Material Balance of DOWA Group

The DOWA group identifies the input of resources and energy into the business activities of the DOWA group ("INPUT") and the output of products produced and the discharged amount of substances imposing environmental burden ("OUTPUT") in each stage of its lifecycle in a quantitative way and conduct business considering material balance.

Resource-Recycling in Society and Our Resource-Recycling

We can look at our business from two sides: product manufacturing business where metal materials and semiconductors are produced and environmental business of wastes recycling, processing and soil remediation.

We not only contribute to society through our business activities but also make use of most of the waste generated in the product manufacturing business as raw materials after they are recycled in the environmental business. Also in the environmental business we effectively utilize heat generated when waste are incinerated in the waste treatment process. This waste heat is recovered as steam and electricity and we use them in other processes as energy. These examples show we use materials and energy within the group and conduct our business with consideration of resource-recycling.

Material Balance of 2013

Environmental burden outside Japan increased compared to last year, as three new companies started operation outside Japan in 2013.

INPUT

INPUT

The amount of purchased power and fossil fuel consumption increased in connection with increased production and treatment. Total amount of energy input increased by 11% compared to previous year. As for total material input, accepted waste increased by 9% and amount of materials used increased by 4% compared to previous year.

OUTPUT

OUTPUT

Total emission of GHG (greenhouse gas) increased by 16% compared to previous year as a result of increased energy input and worse electricity emission factor in Japan. As for total waste recycling that occurred, material recycling increased dramatically by 29% compared to previous year, while the amount of wastes decreased by 5% compared to previous year.

For details of each item, see following pages.

![]() Zoom

Zoom

Our Measure to Fight against Global Warming

The DOWA group set a goal of “15% reduction of specifi c consumption of CO2 by 2020, compared to 1990” according to the Action Plan to Implement Low Carbon Society by Nippon Keidanren (Japan Business Federation) and the Japan Mining Industry Association (published as of January 2013) as a measure to fi ght against global warming.

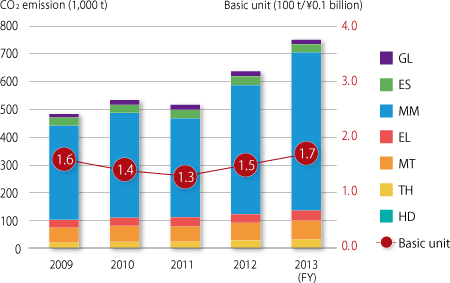

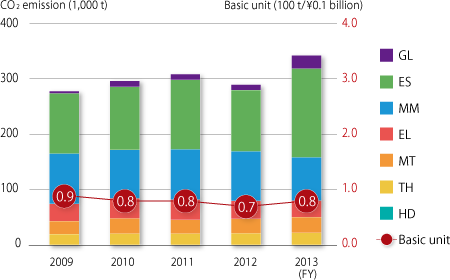

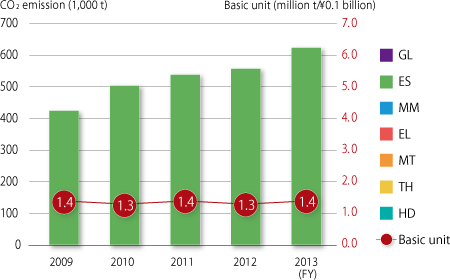

Changes of Emission of GHG

Changes of Emission of GHG

The CO2 emission derived from GHG in 2013 was, 1,718,000 t–CO2 (1,677,000 t-CO2 in Japan and 40,000 t-CO2 outside Japan). The CO2emission from GHG in Japan increased by approximately 16%. It is attributable to increase of power consumption resulted from the increased zinc production in Akita Zinc and increase of fossil fuel consumption in connection with the increased processing of wastes in Eco-System Okayama. Outside Japan, mainly CO2 emission derived from fossil fuel increased. This is attributable to addition of three plants in Asian countries in 2013.

We will continue to promote measures for effective use of energy and conduct activities to reduce CO2 emission on a daily basis.

We accept wastes from other companies outside the DOWA group for incineration in our plants. Therefore, their CO2 emission accounts for a large part of our CO2 emission. As it is difficult to control the amount of wastes we receive from other companies and reduce CO2 emission, we try to increase thermal recycling through power generation using heat and steam from incinerating those wastes.

We also use heat from incinerated wastes for destruction of CFC that destroys the Ozone layer and alternative for CFC such as HFC and PFC, which are the cause of global warming.

<Derived from electricity>

<Derived from fossil fuel>

<Derived from wastes only in Japan>

Our CO2 Reduction Efforts in 2013

We changed the type of fuel and introduced LED lighting for our equipment and facilities. We stopped a new capital investment and reduced the temperature of air conditioning to save energy. We made a modal shift to railways and ships that emit less CO2. We also tried to collect and deliver products more effectively.

|

Amount of CO2 reduction 116t/year |

|

Amount of CO2 reduction 7,600t/year |

|

Amount of fuel reduction 37.9 kl/year |

|

Amount of CO2 reduction 8.6t/year |

Note:

CO2 is calculated by multiplying grid-purchased electricity, fossil fuel consumption and amount of accepted waste by emission factor set forth in the Act on Promotion of Global Warming Countermeasures. However, CO2 emission derived from accepted waste does not always correspond to the value submitted to administration authorities, because part of the prerequisites used in the method for this report differ from that for the reports to administration authorities. As segregation of waste differs between Japan and other countries, it is difficult to set a proper emission factor to such emission. Therefore CO2 emission derived from waste shown here are only from our business entities in Japan.