Priority Measure - Reducing Environmental Impact & Risks

Safety Management of Suspended or Abandoned Mines and Tailing Dams

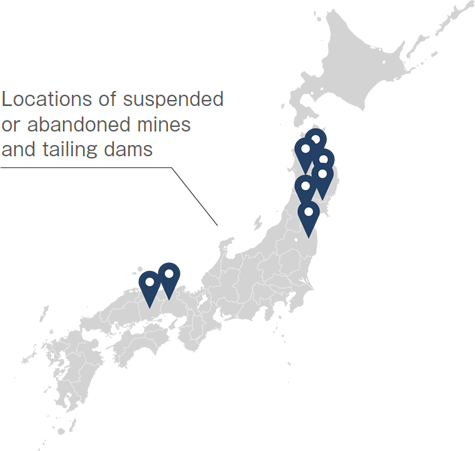

In the past, many mines were operating in Japan, but from around 1970, such things as the rapid appreciation of the yen reduced profitability, and forced many domestic mines to stop operating. At present, along with tailing dams that are adjoining facilities of these suspended or abandoned mines, under various mining laws and procedures such as the Mine Safety Act, they are strictly managed by the company or local government that ultimately held the right to operate the mine.

We currently operate and manage more than 20 suspended or abandoned mines and more than 30 tailing dams, the majority of which have been suspended or abandoned. In addition, by managing with voluntary management standards that are stricter than mining laws and procedures, we are working to prevent mine pollution and maintain and improve safety.

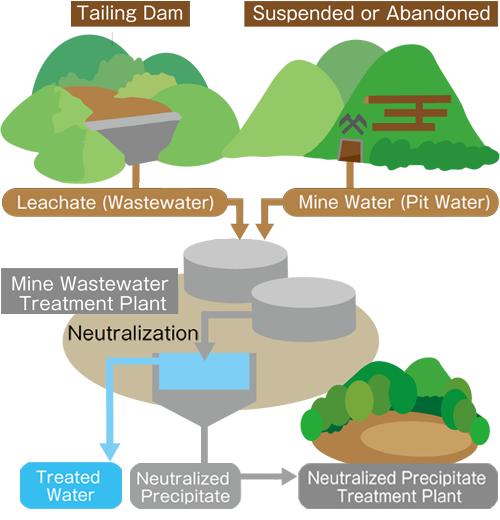

Management of water resources

In suspended or abandoned mines, as a result of excavated tunnels, some of the ore remaining in the mines comes into contact with groundwater and oxygen in the air, causing an oxidation reaction. There is the possibility that acidic water or mine water (pit water) containing heavy metals will flow out from the pithead. In addition, at tailing dams, leachate (wastewater) containing harmful heavy metals is discharged due to rainwater or groundwater, and there is the risk of it flowing into rivers, causing pollution of water quality and agricultural land.

We have set up mine wastewater treatment plants near each facility, we monitor pit water and wastewater generated from tunnels and tailing dams 24 hours a day, 365 days a year, and perform appropriate treatment according to the quality. Through this, we are working to maintain healthy water circulation and a sustainable water use environment.

HAREYAMA Satoshi, Representative Executive Director, UNEKURA MINING

HAREYAMA Satoshi, Representative Executive Director, UNEKURA MINING