The Environment of DOWA

The Dowa Group positions environmental conservation initiatives as an important issue for management, and we promote environmental management.

Basic Environmental Policy

We have formulated our basic environmental policy with the following basic concepts: “DOWA's business activities themselves are to improve the environment, and we are working with the aim that the next generation can inherit a good global environment” and “in our daily business activities we consider good things for the global environment and regions, and by taking actions that are esteemed by the local people, we establish fairness and integrity as our corporate culture in the actions and awareness of Dowa Group employees”.

Environmental basic policy http://www.dowa-csr.jp/en/csr/csr_policy.html

Environment Management System

The DOWA Group's environmental management activities are coordinated by the environment & safety department and the planning offices of each operating company that conducts environmental conservation activities.

Together with adjusting and coordinating things between each of the operating companies, DOWA Holdings conducts environmental management and compliance management for the entire DOWA Group.

In addition, we have acquired ISO 14001 certification at major domestic production sites and overseas offices, and for the proper implementation of environmental management, we do regular internal and external audits, and we are working to support the training of internal auditors through auditor training courses.

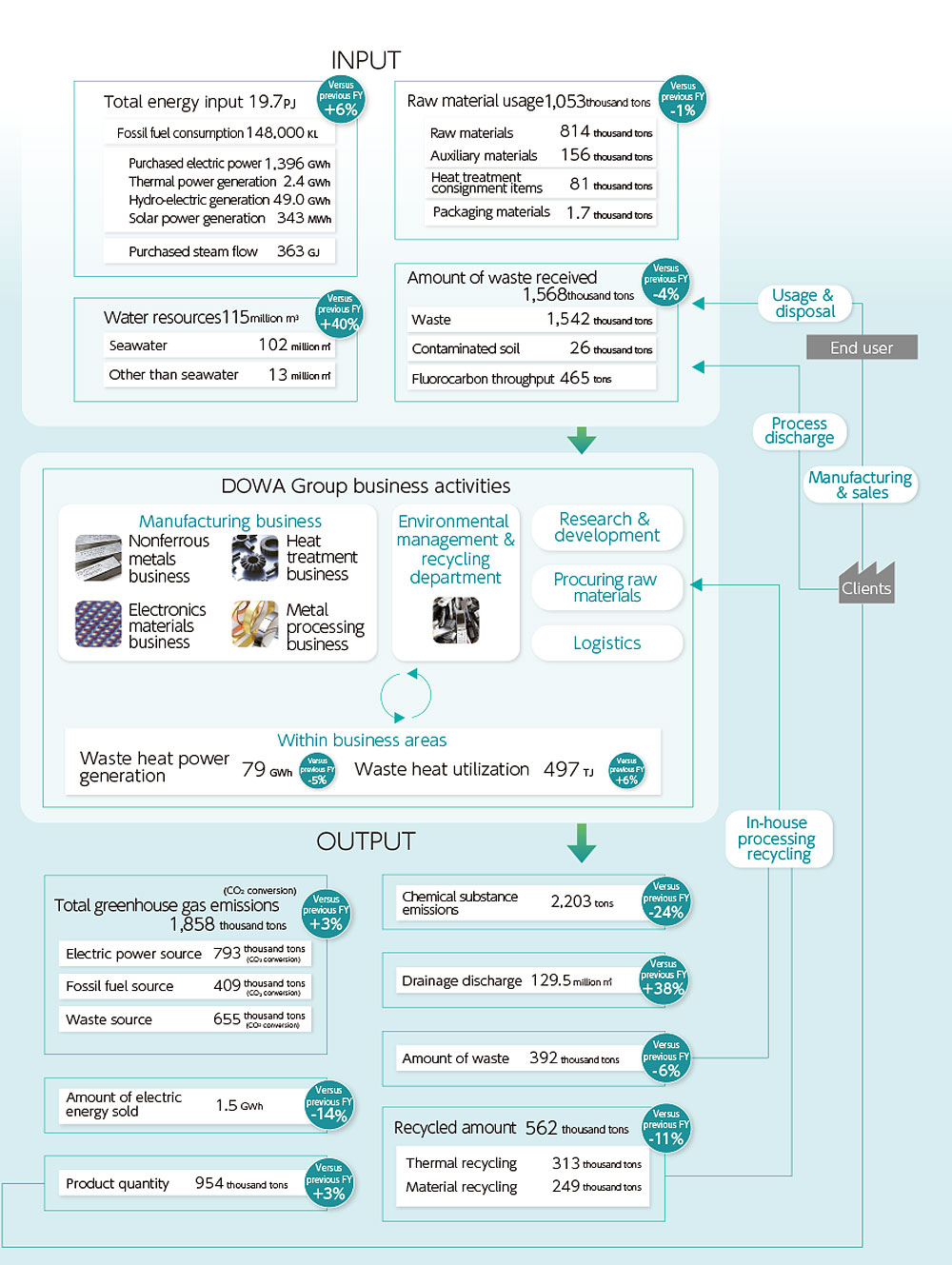

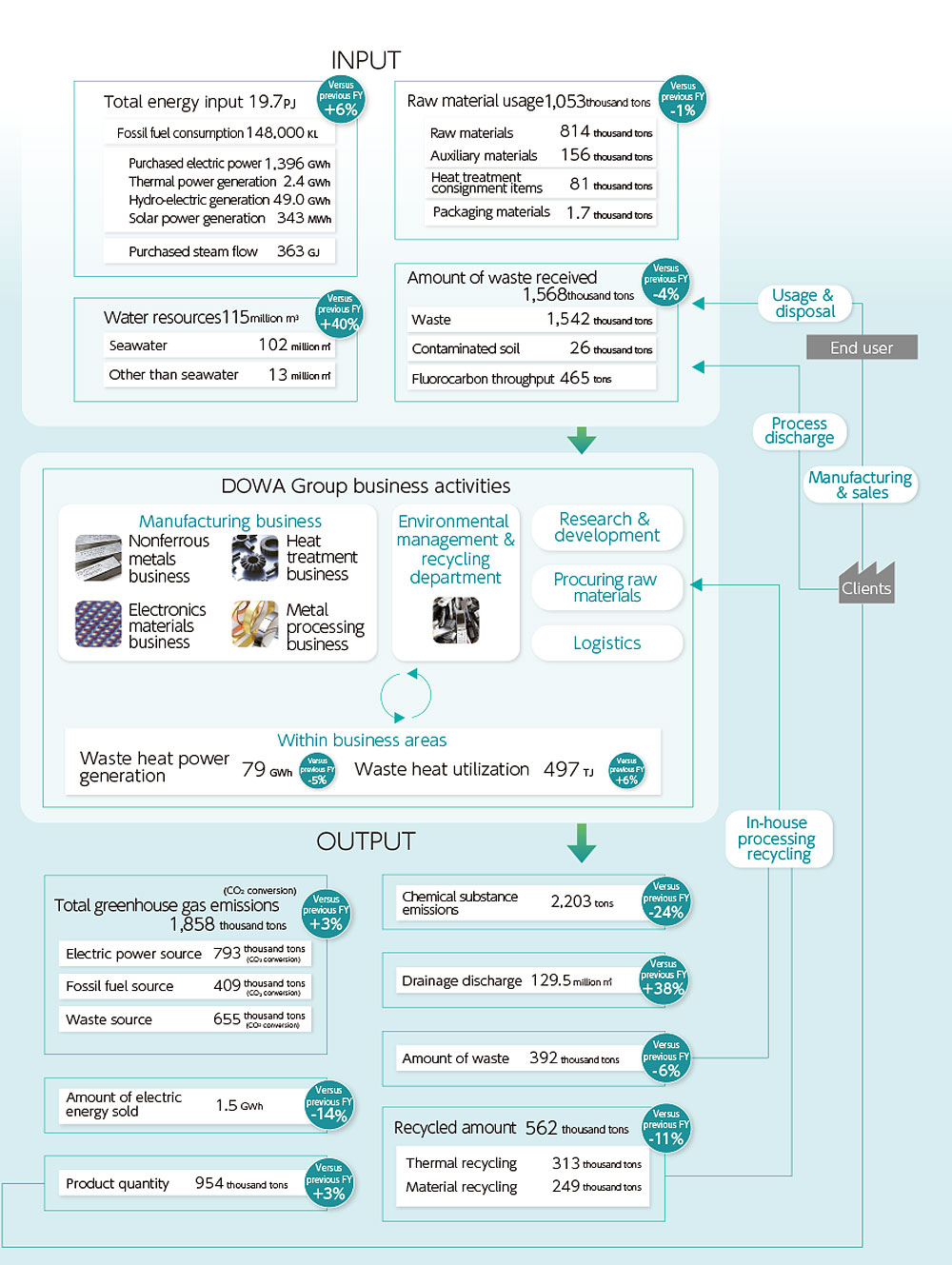

Material Balance for 2017

With regards to CO2 emissions, in principle we seek to multiply the electric power system purchase amount, the fossil fuel consumption and the amount of waste received, by the emission factor in the Law Concerning the Promotion of Measures to Cope with Global Warming.

With regards to CO2 emissions derived from waste received, because the calculation terms are set for preparing this report, it may not necessarily match with the number reported to government agencies. In addition, due to differences in the classification of waste in Japan and overseas, and the difficulty in setting an appropriate emission factor for waste received at overseas business sites, for CO2 emissions originating from waste, only the portion for Japan business sites is shown.

Along with the review of the aggregate, some of the figures reported in the 2017 CSR Report have also been revised.

About the Current Situation of the Environment

Initiatives to Prevent Global Warming

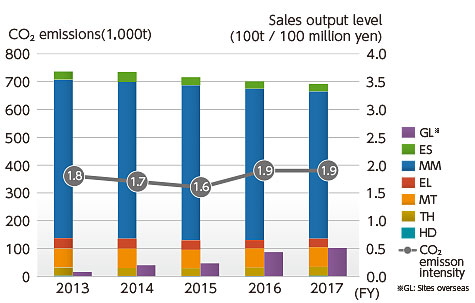

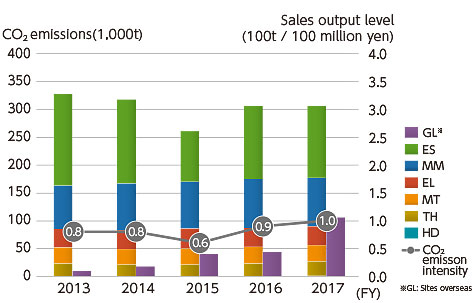

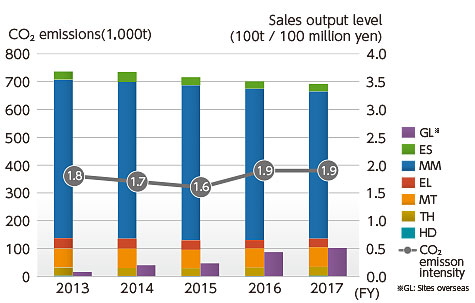

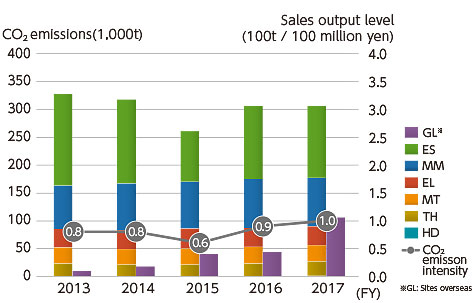

At the DOWA Group, based on the Action Plan to Implement a Low Carbon Society by the Keidanren (Japan Business Federation) and the Japan Mining Industry Association (announced in January 2013), we have set a goal of“ a 15% reduction in our CO2 emission rate by FY 2020, compared to FY 1990”.

Reduction of Greenhouse Gas Emissions

In FY 2017, the greenhouse gas emissions by the DOWA Group as a whole were about 1,858 thousand tons CO2 (1,649 thousand tons in Japan and 208 thousand tons overseas). Compared to the previous FY, it increased by 3%.

Domestic emissions decreased by about 2%. Despite an increase in target facilities and the full-scale operation of new plants, energy consumption was reduced due to switching to energy-efficient equipment and appropriate operation management.

On the other hand, overseas it increased by 58% compared with the previous FY due to expanded waste logistics in Indonesia and Thailand, and increased use of fossil fuels in line with business expansion in India.

Electric power source

Fossil fuel source

Major initiatives

for FY 2017

- Facility remodeling & process improvement……7 sites

- Miniaturization of equipment, and reduction of the number of units……3 sites

- Switch to high efficiency type lighting equipment……12 sites

- Reduction of equipment standby time, and planned shutdowns……5sites

- Waste heat utilization, and waste power generation ……8sites

Initiatives for Renewable Energy

We are working on global warming measures through utilization of in-house power generation by renewable energy, and the dissemination of renewable energy through our business.

Utilizing renewable energy

At Kosaka Smelting & Refining (Akita Prefecture), in 1897 we began operating a hydroelectric power plant for the use of mine development, only the second such plant in Japan.

Since then, as we expanded our business, we continued to expand and improve our facilities, and now we have six hydroelectric power plants in Akita Prefecture.

In FY 2017, we generated 49.0 GWh, which is an important power source to cover the energy of Kosaka Smelting & Refining.

In addition, we are introducing photovoltaic power generation systems at the Ohta Plant of Thermoengineering (Gunma Prefecture), DOWA Hightech (Saitama Prefecture), Eco-System Sanyo (Okayama Prefecture) and Act-B Recycling (Kumamoto Prefecture).

In FY 2017, the total power generation of the four companies was 343Wh, and it is used for part of our electric power needs in our business activities.

Initiatives through business

DOWA Hightech is one of the world's largest manufacturers to produce "silver powder" which is used in the electrode sections of solar battery cells (crystal silicon type solar batteries).

The silver powder for electrodes is required to have such properties as low resistance and high definition wiring, and it is positioned as an important material that greatly impacts product performance.

By developing and providing optimal silver powder for the needs of domestic and overseas manufacturers, and supplying it stably, we are greatly contributing to the improvement of solar battery performance.

E&E Solutions is an environmental consulting company that carries out numerous support activities for introducing renewable energy such as solar power, wind power and biomass generation.

They are working on the spread of renewable energy through such things as predicting mega solar power generation, technical verification and risk assessment of power generation equipment, and environmental assessments of offshore wind power generation.

Conservation of water resources

Every year the DOWA Group confirms the status for water intake sources and drainage destinations in addition to water usage at production sites in Japan and overseas,

We are working to reduce the amount of water used throughout the entire group by promoting efficient use within business sites to reduce the quantity of water intake.

Use of water resources

In FY 2017, the water resource input amount was 114.6 million m3, an increase of about 40% from the previous FY.

This was due to an increase in the amount of seawater used as cooling water for smelting.

After using the cooling water in the process, we confirm the water quality, and it is all returned to the original sea area except for the evaporated portion.

Meanwhile, the amount of freshwater used was 12.7 million m3, a decrease of about 4% from the previous FY.

In FY 2017, we worked on reducing the amount of water usage by installing water-saving type equipment and recycling usage within processes.

Drainage water

In FY 2017, the total amount of drainage water was 130 million m3, an increase of about 38% from the previous FY.

At each business site, we are working to preserve water quality, not only observing drainage water regulations through sound drainage water management, but also strict voluntary standards.

Amount of water resources used

Conservation of biodiversity

Based on the basic policy of biodiversity, the DOWA Group is working to minimize the impact that our business activities have on biodiversity, and we are promoting the conservation of biodiversity through social action programs.

Basic policy of biodiversity

The DOWA Group recognizes that our business activities get benefits from a biodiverse nature, and the conservation of biodiversity is important to keep enjoying these benefits. As a member of society, we will voluntarily and continuously work on the conservation of biodiversity and sustainable usage.

http://www.dowa-csr.jp/en/csr/biodiversity.html

Consideration for biodiversity in procurement

Supplying paper, a forest resource, is one of the important ecosystem services, and it is also related to climate change and waste

Because the DOWA Group's manufacturing business is mainly in the area of non-ferrous metals, we do not use biological resources for our main raw materials, excluding water, but we use paper at all our business sites both in Japan and overseas, and our whole group purchases a lot of paper every year.

For this reason, we use paper that is a mixture of old paper and forest certified wood pulp for copy paper and pamphlets, and we are working to use sustainable biological resources.

When selecting suppliers of paper for FY 2017, in addition to the environmental nature of the paper itself, based on the CSR procurement policy, we confirmed that suppliers are considering biodiversity through "responsible paper procurement".

Confirmation items for "responsible paper procurement"

- Establishment of a procurement policy for wood feedstock

- Establishment and operation of a management system that confirms the legality of the wood feedstock

- Can provide information about the supplier of raw material pulp

Resource Recycling Initiatives

At the DOWA Group, among the SDGs goals, “12. Securing sustainable patterns of consumption and production” is the area in which we are most closely involved, and we believe that we can show a great contribution towards the achievement of the goal.

By working on resource recycling through our technology and resources, we aim to achieve goal No. 12.

At the DOWA Group, among the SDGs goals, “12. Securing sustainable patterns of consumption and production” is the area in which we are most closely involved, and we believe that we can show a great contribution towards the achievement of the goal.

By working on resource recycling through our technology and resources, we aim to achieve goal No. 12.

In the resource recycling of the DOWA Group there are three main loops.

First, is in-house generation and usage, for waste generated in the "manufacturing business", such as our smelting and metal processing, it is recycled in the "environmental business" and "smelting business"

Besides selling it as metallic material, we re-use it as raw material for our company.

Second, is accepting and recycling scrap metal generated from the processes of manufacturing plants at other companies.

In case it is from client factories that supply our materials or parts, such things as reusing the accepted waste as raw material leads to a reduction of new resource inputs.

Third, is the recycling of used end products.

Through electrical appliance recycling, automobile recycling and the recycling of small household appliances, used products widely recovered from society will be returned to society as metallic material again.

In addition, with regards to paper, iron and aluminum, etc., that we cannot recycle, we strive to appropriately recycle through the recycling processes of other companies.

In addition, with regards to paper, iron and aluminum, etc., that we cannot recycle, we strive to appropriately recycle through the recycling processes of other companies.

As shown above, at the DOWA Group we are working on effective utilization of limited resources through the three loops, from the production stage of our own company to the waste generated by society.

At the same time, as a social responsibility in resource recycling, together with striving to minimize the environmental burden at every stage of recycling, such as appropriate water treatment, detoxifying waste and reliable final disposallandfill, we are aiming for sustainable resource recycling that considers environmental conservation and energy savings, such as using heat generated in the disposal treatment process as steam or electric power.

OUTPUT

- ●Products

- The product shipment volume in FY 2017 was 954 thousand tons, an increase of about 3% from the previous FY.

This was mainly due to an increase in the shipment of zinc products and an increase in the number of heat treatment furnaces manufactured.

- ●Recycling

- The amount of thermal recycling in FY 2017 was 313 thousand tons, a decrease of approximately 15% from the previous FY.

Of this, 311 thousand tons was recycled within the DOWA Group, and 2,000 tons was recycled outside of the company.

The amount of material recycling in FY 2017 was 249 thousand tons, a decrease of approximately 5% from the previous FY.

Of this, 122 thousand tons was recycled within the DOWA Group, and 126 thousand tons was recycled outside of the company.

- ●Discharged waste

- The amount of waste disposal treatment in FY 2017 was 392 thousand tons, a decrease of approximately 6% from the previous FY.

This was due to the recycling of some paper which until now had been waste.

TOPICS

Metal recovery of incinerated ash and recycling

In December 2017, at Meltech Iwaki in Iwaki, Fukushima Prefecture, we started operation of incinerated ash melting treatment and artificial manufacturing aggregate facilities, the second domestic site following Meltech in Tochigi Prefecture.

In December 2017, at Meltech Iwaki in Iwaki, Fukushima Prefecture, we started operation of incinerated ash melting treatment and artificial manufacturing aggregate facilities, the second domestic site following Meltech in Tochigi Prefecture.

For incinerated ash generated from municipal waste disposal treatment facilities, much of it is landfilled at final disposallandfill sites, but for the purpose of improving the recycling rate and securing capacity at the final disposal sites, municipalities that choose recycling such as melting treatment are on the rise. Since 1999, at Meltech, through a unique treatment process that melts the incinerated ash in a reduced state and cools it over time, molten slag used as artificial aggregate, and molten metal containing gold, silver, copper and other valuable metals, have been manufactured.

With the new operation at Meltech Iwaki, we are introducing the same treatment process as Meltech, which has an operational track record of about 20 years, and are accepting incinerated ash from municipalities, including the city of Iwaki where Meltech Iwaki is located.

By organizing melting treatment at two facilities, our ash melting and recycling capacity has doubled to about 90,000 tons per year, and we are responding to the needs of customers who want to make effective use of incinerated ash as a resource.

Since 1999, at Meltech, through a unique treatment process that melts the incinerated ash in a reduced state and cools it over time, molten slag used as artificial aggregate, and molten metal containing gold, silver, copper and other valuable metals, have been manufactured.

With the new operation at Meltech Iwaki, we are introducing the same treatment process as Meltech, which has an operational track record of about 20 years, and are accepting incinerated ash from municipalities, including the city of Iwaki where Meltech Iwaki is located.

By organizing melting treatment at two facilities, our ash melting and recycling capacity has doubled to about 90,000 tons per year, and we are responding to the needs of customers who want to make effective use of incinerated ash as a resource.

Molten slag has a strength that is equivalent to natural stone, and because hazardous heavy metals are separated out and it is environmentally safe, the artificial aggregate that is used as roadbed material for streets is highly valued.

In addition, for molten metal containing valuable metals, Kosaka Smelting & Refining of the DOWA Group recycles gold, silver, copper and other metals as smelting raw materials.

At the DOWA Group, we will contribute to achieving the SDGs by promoting recycling and the appropriate processing of waste, such as expanding the incinerated ash melting treatment and artificial manufacturing aggregate businesses.

At the DOWA Group, among the SDGs goals, “12. Securing sustainable patterns of consumption and production” is the area in which we are most closely involved, and we believe that we can show a great contribution towards the achievement of the goal.

By working on resource recycling through our technology and resources, we aim to achieve goal No. 12.

At the DOWA Group, among the SDGs goals, “12. Securing sustainable patterns of consumption and production” is the area in which we are most closely involved, and we believe that we can show a great contribution towards the achievement of the goal.

By working on resource recycling through our technology and resources, we aim to achieve goal No. 12.

In December 2017, at Meltech Iwaki in Iwaki, Fukushima Prefecture, we started operation of incinerated ash melting treatment and artificial manufacturing aggregate facilities, the second domestic site following Meltech in Tochigi Prefecture.

In December 2017, at Meltech Iwaki in Iwaki, Fukushima Prefecture, we started operation of incinerated ash melting treatment and artificial manufacturing aggregate facilities, the second domestic site following Meltech in Tochigi Prefecture.  Since 1999, at Meltech, through a unique treatment process that melts the incinerated ash in a reduced state and cools it over time, molten slag used as artificial aggregate, and molten metal containing gold, silver, copper and other valuable metals, have been manufactured.

With the new operation at Meltech Iwaki, we are introducing the same treatment process as Meltech, which has an operational track record of about 20 years, and are accepting incinerated ash from municipalities, including the city of Iwaki where Meltech Iwaki is located.

By organizing melting treatment at two facilities, our ash melting and recycling capacity has doubled to about 90,000 tons per year, and we are responding to the needs of customers who want to make effective use of incinerated ash as a resource.

Since 1999, at Meltech, through a unique treatment process that melts the incinerated ash in a reduced state and cools it over time, molten slag used as artificial aggregate, and molten metal containing gold, silver, copper and other valuable metals, have been manufactured.

With the new operation at Meltech Iwaki, we are introducing the same treatment process as Meltech, which has an operational track record of about 20 years, and are accepting incinerated ash from municipalities, including the city of Iwaki where Meltech Iwaki is located.

By organizing melting treatment at two facilities, our ash melting and recycling capacity has doubled to about 90,000 tons per year, and we are responding to the needs of customers who want to make effective use of incinerated ash as a resource.