DOWA group is committed to carrying out business activities rooted in the countries and regions where overseas expansion is carried out, and to building and developing relationships.

In addition, all the factories are conscious of being a member of the local community, and at the same time, aim to contribute to the development of the region from a global perspective.

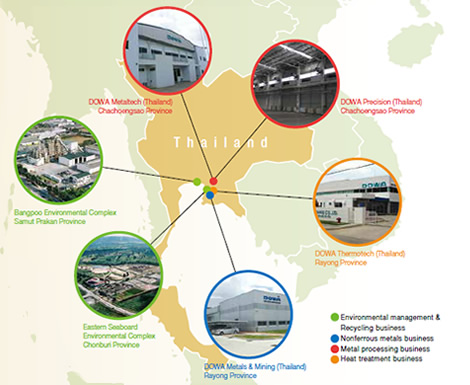

Thailand, which is located in the heart of Asia and making advances in the infrastructure development, is indispensable in the supply chain in the global economy. Since our business expansion in 2006, DOWA group has expanded into 4 businesses namely environment and recycling, smelting, metal processing, and heat treatment, and currently these are our flagship overseas bases. Here we introduce the business activities of DOWA group in Thailand and CSR initiatives in respective offices.

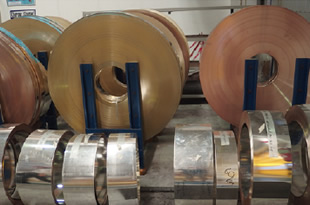

Business development of DOWA Group in Thailand began with the establishment of the DOWA Metaltech Thailand (DMTT) to carry out the copper products plating processing. DMTT is located in Chachoengsao Province, Gateway City Industrial Estate, and provides silver, nickel, tin-plating and copper and copper alloys in the form of coils, called strips, mainly for Japanese manufacturers of auto parts. We meet the needs of Japanese companies by promoting local procurement in Thailand, by means of mass production with quality comparable to Japan, by having the same state-of-the-art facilities as the factories in Japan.

Utilizing the network of DOWA group, DMTT has been building a recycling flow of scrap metal to be discharged from the process. We promote recycling not only in our own companies but also as a customer service, by purchasing the scrap of sold copper and brass products. Precious metal used in plating is recovered in Singapore and Kosaka smelting & refining (Akita), and copper is recovered in DOWA metal (Shizuoka). In order to reliably perform such international resource recycling, every year, we send a detailed administrative report that clarifies the traceability of process steps to the Government of Thailand, and promote responsible recycling based on properly managed recycling system.

As DOWA Thermotech's No.1 base in Southeast Asia, DOWA Thermotech Thailand (DTT) is located in the Eastern Seaboard Industrial Estate in Rayong Province, about 150 km from Bangkok, where automotive industry is concentrated. More than 100 equipment by DOWA Thermotech have been installed in Thailand so far, and DTT started with repair and maintenance, and remodeling services for these equipment. At present, it focuses on maintenance service of DOWA-made heat treatment equipment and commissioned processing of heat treatment services mainly for automotive parts and agricultural machinery parts.

In DTT, we are focused on local human resource development such as accepting internships from high schools nearby, and carrying out tests as heat treatment professional skills similar to Japan, as part of technical education. We have started safety activities such as CCCF (Completely Check and Completely Find- Out) since 2011, and QC (Quality Control) since 2014. In CCCF activities, in addition to imparting training related to activities to the employees, we also isolate any hazards in the workplace, through "on-site activities" which is conducted 2 times a years and in which all the employees participate. Further, we are working on visualization of information and communication with employees, by installing a safety bulletin board.

Bangpoo Environmental Complex (BPEC) is the waste incineration and recycling plant in the Bangkok suburb of Samut Prakan. It is one of the only 2 large waste incineration facilities in Thailand. It started operations in 2006 and joined DOWA group in 2009. BPEC carries out incineration of product waste such as shampoo and cigarettes, and non-hazardous waste discharged from factories, offices, and cafeterias etc. in the vicinity. It has maintained particularly high occupancy rates among the incineration facilities in Thailand and has stable operations.

In Thailand, lack of collection and processing capabilities against the increased waste generation due to economic growth has become a social issue. As cost is an issue, landfilling the waste without any incineration is commonplace. Therefore, there are problems such as hygiene and nuisance odor. There are also improper waste treatments such as open burning and illegal dumping.

BPEC has a fluidized bed incinerator built in 2005 as effective waste utilization project supported by Japan's New Energy and Industrial Technology Development Organization (NEDO) and carries out reliable incineration process at a high temperature of 950°C. Further, simultaneously with incineration, the steam collected from boiler is supplied as a heat source to the nearby factories and remaining steam is used for power generation. In addition to being consumed inhouse, the surplus generated power is sold to the power companies, thus ensuring both an energy supply and a safe and environment friendly waste disposal.

Eastern Seaboard Environmental Complex (ESBEC) is located in Sriracha City in Chonburi province of Thailand. ESBEC is engaged in recycling business such as waste oil and waste liquid treatment, final disposal of waste, and separate collection of metal scrap and plastic from recycling of waste oil and sludge and waste electrical and electronic products. ESBEC's final treatment facility is also compliant with construction standards of US Environmental Protection Agency (EPA). ESBEC takes thorough environmental measures such as measures against offensive odors by using high density polyethylene sheets, incineration of methane compounds generated from such garbage, and physicochemical treatment and biological treatment of leachate.

In order to contribute to the development of Thailand, ESBEC is actively engaged in activities from the viewpoint of integration with local community and education of children who are bearers of the future. Especially, as the development of the next generation, ESBEC has scholarships to 6 elementary and junior high schools in the region, and financial support to the faculty development fund. In addition, it continues to carry out contribution activities that are deeply associated with core business, such as donation for sorting out trash to promote recycling, volunteering for cleaning and disinfection for improving the sanitary environment of schools, and study tours of offices for the students, as part of the environmental education.

DOWA Metals & Mining (Thailand) Co., Ltd. (DMMT) is a zinc processing plant which is located in Amata city industrial estate, in Rayong Province, 120 km southeast of Bangkok. It is engaged in local production of high-quality zinc processed products mainly for automotive industry, such as formulated zinc for molten zinc plating, zinc alloy for die-casting, and thermal spray zinc line.

DMMT has joined the association that carries out CSR volunteering in the Amata city industrial estate. Since 2014, 10 companies, mostly Japanese companies have participated and initiatives are being undertaken while ideas for the region being discussed among the regional representatives and the companies. This activity is for the purpose of communication with local residents and we have been carrying it out activities such as measures against hot weather in schools in the neighborhood, and ventilation measures for school cafeteria. In FY2015, we are thinking about a community participation manufacturing contest, utilizing the waste from processes in the factories that participate voluntarily, and call the local residents for participation in order to further enhance the activities.