The DOWA group is committed to promoting manufacturing of environmentally-friendly eco-products throughout the entire life cycle of the products from manufacturing to disposal. In the four areas of 1) Materials, 2) Components, 3) Products and 4) Services, we strive to develop and manufacture environmentally-friendly products and services contributing to conservation of resources. We call them "Eco-Products" in the following phases:

A. At manufacturing process (to reduce environmental burden when we manufacture our products)

B. In use (by providing materials and parts that contribute to energy saving and reduction of environmental burden of end products)

C. At disposal (metal recycling and waste disposal after they are used)

Wide Range of Application such as Sterilization |

DOWA Electronics |

|---|

Eco-product classification 3) Products / B. In use -> energy saving and C. At disposal -> reduction of hazardous substances

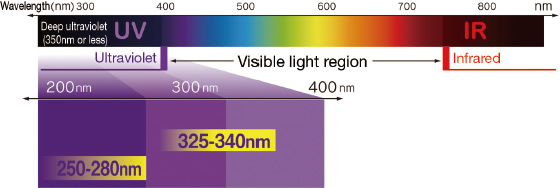

The ultraviolet region is outside the lower limit of visible light that human beings can sense. It is used in a wide variety of applications, including industry and medicine, capitalizing on its characteristic of long wavelength and powerful energy. The main application of a light source outside of the ultraviolet region used to be an electrical discharge tube such as mercury-vapor lamps. However, as people have recognized mercury as hazardous they were converted to LEDs that have lower power consumption.

The ultraviolet region is outside the lower limit of visible light that human beings can sense. It is used in a wide variety of applications, including industry and medicine, capitalizing on its characteristic of long wavelength and powerful energy. The main application of a light source outside of the ultraviolet region used to be an electrical discharge tube such as mercury-vapor lamps. However, as people have recognized mercury as hazardous they were converted to LEDs that have lower power consumption.

Recently "near-ultraviolet" wavelengths of 405nm, 380nm and 365 nm have been commercialized. Deep-ultraviolet LEDs that use the wavelength of 350nm or less were expected to be promising for sterilization, but from the technical point of view their manufacturing was considered difficult. However, DOWA Electronics has succeeded in their commercialization by combining DOWA's proprietary technologies.

We can enjoy the merits of deep ultraviolet LEDs that have a longer life and less power consumption by replacing traditional mercury vapor lamps with them. We can also realize mercury free products. Mercury vapor lamps emit light of other wavelengths in addition to wavelengths around 260nm that is considered most useful for sterilization. Compared to deep ultraviolet LEDs, mercury vapor lamps are less energy efficient, generate more heat, more power consumption and are larger in size. On the contrary, deep ultraviolet LEDs can emit light of specific wavelengths more efficiently and they do not take up much space. As they are mercury free, they contribute to reduction of hazardous substances. Mercury vapor lamps emit light of wavelengths that generate ozone. LEDs enabled emitting light of specific wavelengths only, reducing ozone generation.

Application of conventional electrical discharge tubes for medical and biotechnological fields used to be difficult. However, development of these LEDs towards those new applications is in progress as the next generation light source, capitalizing on their characteristics. Many companies in the world expect much in terms of realizing the full of potential from deep ultraviolet LEDs that contribute to the reduction of environmental burden.

Environmentally - friendly Surface Treatment "Chrome Doppe N" Extends Life Cycle of Metallic Mold. |

CEMM, Co., Ltd. |

|---|

Eco-product classification 4) Services / B. In use -> energy saving, prevention of global warming and extension of product life cycle

Chemical and physical treatment can add corrosion resistance and heat resistance properties as well as special characteristics and functionalities to the surface of metal materials. The surface treatment is the technology indispensable for extending life cycle of metal parts and molds. There are many surface treatment technologies, including diffusion coating, surface hardening method and coating method. The DOWA group has more than 20 types of surface treatment technologies. Among them is the "Chrome Doppe N" offered by CEMM of the DOWA Thermotech group. This is an eco-friendly excellent coating technology created by physical vapor deposition. This method is used mainly for molds to form powders, on plastics and rubber to enhance resistance to corrosion, for wear resistance and for die releasing properties, resulting in prolonging the life cycle of molds dramatically.

Chemical and physical treatment can add corrosion resistance and heat resistance properties as well as special characteristics and functionalities to the surface of metal materials. The surface treatment is the technology indispensable for extending life cycle of metal parts and molds. There are many surface treatment technologies, including diffusion coating, surface hardening method and coating method. The DOWA group has more than 20 types of surface treatment technologies. Among them is the "Chrome Doppe N" offered by CEMM of the DOWA Thermotech group. This is an eco-friendly excellent coating technology created by physical vapor deposition. This method is used mainly for molds to form powders, on plastics and rubber to enhance resistance to corrosion, for wear resistance and for die releasing properties, resulting in prolonging the life cycle of molds dramatically.

Surface treatment requires temperature of approximately 500 - 930℁Ein plasma nitriding and gas carburizing methods, while the Chrome Doppe N method uses plasma energy under approximately 200℁Ein the reduced pressure environment. Therefore in this method deformation and change in shape are unlikely to happen. This method can be used for a variety of materials, resulting in energy saving and reduction of CO2. In addition, this is a safe coating free of cadmium and lead.