DOWA Metals & Mining is responsible for the core business of the DOWA group of mining, smelting and refining and employs a unique business model that is integrated with environmental business activities, by securing resources through investment in and financing to overseas mines and by way of high quality smelting and refining technologies that produce key materials. Our major plants of Kosaka Smelting & Refining as well as Akita Zinc are positioned as the core; it has become to be the world's best flexible recycling smelting complex. In Kosaka Smelting & Refining while we treat various recycling materials inside and outside of Japan including mobile phones and circuit boards from PCs in our TSL furnace, we also commenced recovering of nickel and tin as new metals to diversify metal elements we recover. From the viewpoint of global environmental conservation and securing resources, we also started operation of the world's first scorodite process that could recover and detoxify hazardous substances. Akita Zinc is committed to achieving world highest level of quality and cost effectiveness. We are committed to thorough and effective use of resources including recovery of indium from materials for ITO for flat-screen TVs.

Through these efforts we produce valuable metals using materials from ores and "urban mines" (recycling), aimed at building a resource-recycling society, contributing to reduction of energy consumption and CO2 through effective utilization of limited resources to make the future of our children promising and safe.

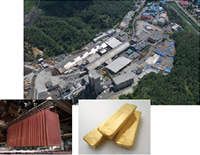

Kosaka Smelting & Refining Co., Ltd.

Address: 60-1 Otaru-be, Kosaka Kozan-aza, Kosaka-machi, Kazuno-gun, Akita Prefecture 017-0202

Employees: 300 (as of the end of March 2012)

Original Place of DOWA Smelter and Refinery with Technology Cultivated by Black Ores

Kosaka Smelting & Refining is a unique complex recycling smelter and refinery in the entire world. The facility can recover precious metals such as gold and silver, as well as rare metals such as bismuth and tellurium in addition to basic metals like copper and lead.

Founded in 1884, Kosaka Smelting & Refining has been engaged in smelting and refining of black ores excavated there for more than 100 years.  Separation and smelting of black ores requires advanced technologies, as they contain more valuable metals and impurities than general copper ores. Kosaka Smelting & Refining succeeded in complete recovery of valuable metals contained in black ores in 1975. Technologies and knowledge with black ores enabled us to establish our position as a complex recycling smelter that can simultaneously smelt and refine ores as well as recycle difficult materials.

Separation and smelting of black ores requires advanced technologies, as they contain more valuable metals and impurities than general copper ores. Kosaka Smelting & Refining succeeded in complete recovery of valuable metals contained in black ores in 1975. Technologies and knowledge with black ores enabled us to establish our position as a complex recycling smelter that can simultaneously smelt and refine ores as well as recycle difficult materials.

Newly Started Operation of Recovering Nickel and Tin

The newly operated TSL Furnace in 2008 enabled 100% smelting of recycling materials such as electronic substrates and mobile phones as opposed to conventional flash furnaces. We also constructed a plant to recover crude sulfated nickel and tin in 2011.

Sulfated nickel and tin are by-products produced in the smelting process of copper and lead. Sulfated nickel is recovered from residues produced in the electrolytic process of copper, while tin is recovered form residues produced in the manufacturing process of the base metal of lead.

Sulfated nickel and tin are by-products produced in the smelting process of copper and lead. Sulfated nickel is recovered from residues produced in the electrolytic process of copper, while tin is recovered form residues produced in the manufacturing process of the base metal of lead.

We started recovering those metals because the ratio of recycling materials increased and the ratio of nickel and tin contained in those materials increased. The amount of nickel and tin contained in ores are less than that in recycling materials. Tin is used for plating and soldering, while nickel is used for plating and as alloy for coins. We will continue to expand and strengthen recovery and recycling of metals indispensable for industries.

Tin is often used for plating and soldering, but most of it is imported from tin mines outside of Japan. Tin concentrate and scrapped household appliances contain a small amount of tin, but we have not actively recovered tin from such appliances as it is not cost-effective. We have strived to develop a process with higher productivity and lower cost (meaning a lower environmental burden). We have encountered various challenges in the process from development through implementation but in a short period of time, we have succeeded in achieving the planned production volume and the better quality than anticipated. We will further contribute to increasing productivity, effective utilization of resources and building a dynamic workplace.

Yasuhiro Inoguchi

Section Chief of the Technical Development Section, Quality Assurance Department, and Team Leader, Tin Smelting Team, Lead Manufacturing Department

Expanding Relationship with Community through Home Land Forestation

Kosaka Smelting & Refining lost a wide range of forests through excavation of mines. We started replanting broad-leaf trees that were originally there in 2005 and the total trees we planted now amount to 100,000. We adopted an afforestation method of mixing a dozen of variety of trees such as Japanese oak (Mizunara) and beech trees to create an environment with rich biodiversity.

The fifth tree planting festival was held in 2011, and approximately 430 people participated in the festival, including  employees of the DOWA group, elementary and junior high school students in neighboring towns and volunteer groups. We planted 4,500 nursery plants. Also participated in the festival were players from the "Akita Northern Happinets," a professional basketball team sponsored by Akita Zinc and their mascot character of "Bicky" for cheerleading. They held a basketball class for students. We plan new and improved events every year.

employees of the DOWA group, elementary and junior high school students in neighboring towns and volunteer groups. We planted 4,500 nursery plants. Also participated in the festival were players from the "Akita Northern Happinets," a professional basketball team sponsored by Akita Zinc and their mascot character of "Bicky" for cheerleading. They held a basketball class for students. We plan new and improved events every year.

I am engaged in a wide range of work including labor management and administration in the Administration Section of the Administration Department. I participated in the largest event of the DOWA Cup during the period of February 25 and 26 as the part of the secretariat. As I am from an area where snow seldom falls, I had difficulty working at the snow-laden side of the Lake Towada. However, I was moved with the sincere and earnest attitudes of student skiers there. The DOWA Cup is run with heartfelt support from many, including the prefecture, local communities, the police, schools and the Ski Association. This is the 22nd Cup. I am proud of being a member of a local corporation that can support growth of children who endeavor to meet their dreams.

Naoki Mori

Administration Section, Administration Department

The 22nd DOWA Cup

The 22nd DOWA Cup

The 22nd DOWA Cup Junior Cross-country, Lake Towada was held at the lake side of Towada, Kosaka-machi, Akita Prefecture. Four hundred and sixty three students from elementary, junior high schools and schools for disabled students participated from Akita, Aomori and Iwate Prefectures. The sixth sit ski event was also held and many students from Hinai School and Hachinohe School participated in the event. The number of participants in the sit ski event is increasing every year. We had a request from those schools to lend sit ski sets for practice at school.