01The DOWA Group’s Basic Environmental Policy

The DOWA Group has established the "Basic Environmental Policy" to position initiatives for environmental conservation as an important issue in corporate management. In addition to conducting business activities based on environmental conservation as a basic way of thinking, the policy promotes environmental management throughout the entire group.

| DOWA Group promotes the establishment of a recycle-oriented society and also aims to provide the good global environment to the next generation through business activities. |

- We will provide customers (customers, regions, etc.) with products and services that contribute to building a resource-recycling oriented society.

- We will reduce the environmental burdens and risks in our business activities.

- The management and employees will together participate in environmental conservation activities.

|

Basic Environmental Policy

Environment Management System

The Environment and Safety Department and the Planning Department of each business office that conducts environment conservation activities, together carry out the environment management activities of DOWA group. DOWA Holdings conducts the adjustments and compilation amongst the business offices and also carries out the environment management and compliance management of the entire DOWA group. In addition, we have acquired ISO14001 for major domestic production sites and international offices, and for proper implementation of the environment management, we are taking efforts for development assistance of internal auditors through the implementation of periodic internal audits & external audits and auditor training courses.

02Initiatives to Prevent Global Warming

At the DOWA Group, while we have been promoting environmental impact reduction through curtailing energy consumption and CO2 emissions by our businesses, we are also actively working to spread new energy throughout our businesses by utilizing in-house power generation with renewable energy.

Reduction of Greenhouse Gas Emissions

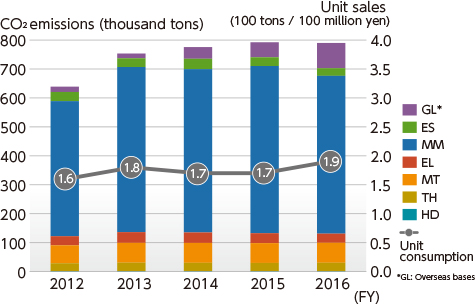

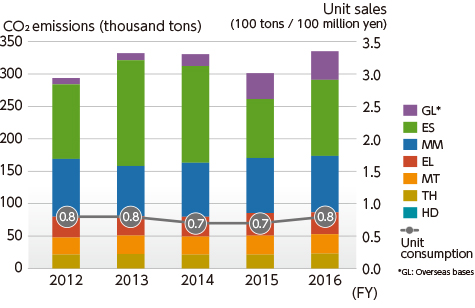

At the DOWA Group, based on the Action Plan to Implement a Low Carbon Society by the Keidanren (Japan Business Federation) and the Japan Mining Industry Association (announced in January 2013), we have set a goal of “a 15% reduction in our CO2 emission rate by FY 2020, compared to FY 1990”.

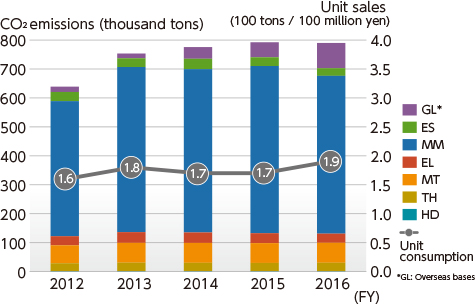

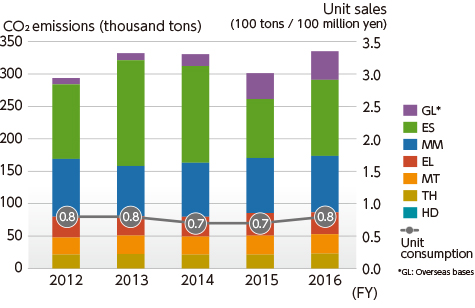

In FY 2016, the greenhouse gas emissions by the DOWA Group as a whole were about 1,595 thousand tons of CO2 (131 thousand tons overseas and 1,464 thousand tons in Japan). While there was an increase overseas due to business expansion in India, since emissions at business sites in Japan declined, greenhouse gas emissions for the entire group decreased by about 4%. Changes in the CO2 emissions of the DOWA Group are largely affected by CO2 emissions resulting from the incineration of waste received from external sources, and it varies depending on the amount and composition of the waste. Since it is difficult to control the amount and composition of externally generated waste, we are working on preventing global warming by promoting thermal recycling that uses the heat generated during incineration for power generation or steam.

Electric Power Source

Fossil Fuel Source

Initiatives for Renewable Energy

At the DOWA Group, to reduce global carbon emissions, we have introduced renewable energy at our businesses, and we are working to expand this through our businesses.

Hydroelectric Power Generation

At Kosaka Smelting & Refining, in 1897 we began operating the second hydroelectric power station in Japan (Oyukawa Choshi Power Station). After that, we continued to expand and improve facilities with the expansion of mining development and our business, and we have six hydroelectric power stations in Akita Prefecture. In FY 2016, we generated 48.3GWh of electricity, and it is an important power source to cover the energy needs of Kosaka Smelting & Refining.

Solar Power Generation

The DOWA Group has introduced solar power generation systems at the Thermo Engineering Ota Plant (Gunma Prefecture), DOWA Hightech (Saitama Prefecture), Eco-System Sanyo (Okayama Prefecture) and Active Recycling (Kumamoto Prefecture). In FY 2016, we generated a total of 332 MWh at the four companies, and it is used as part of the electric power that we need for business activities. In addition, from November 2016, DOWA Eco-System began generating electricity at a mega solar power plant in Odate, Akita Prefecture. The amount of power generated is expected to be 1,561 thousand kWh annually, and all of it will be supplied to Tohoku Electric Power.

The Manufacturing of Silver Powder for Solar Panels

DOWA Hightech is one of the world’s largest manufacturers of “silver powder” used in the electrode sections of solar cells (crystal-based silicon solar cells). The silver powder for electrodes is required to have such properties as low resistance and a high-resolution wiring pattern, and it is positioned as an important material that greatly affects product performance. By developing and offering silver powder that is optimal for the needs of manufacturers in Japan and overseas, and with a stable supply, it contributes greatly to the improvement of solar cell performance.

03Conservation of Biodiversity

Based on the Basic Policy of Biodiversity, the DOWA Group is working to minimize the impact that our business activities have on biodiversity, and we are promoting the conservation of biodiversity through social action programs.

Basic Policy of Biodiversity

The DOWA Group recognizes that our business activities get benefits from biodiverse nature, and the conservation of biodiversity is important to keep enjoying these benefits. As a member of society, we will voluntarily and continuously work on the conservation of biodiversity and sustainable usage.

The Conservation of Biodiversity in Mining Development

The DOWA Group is actively promoting the utilization of recycled materials, such as electronic equipment waste as raw material for smelting, but we also believe that the role of natural ore is important with its stable quality.

For the long-term stable supply of zinc, a main product, in our mid-term plan we are promoting mine exploration and development projects with a goal of over 50% for the zinc ore ratio. But since mining development and operations have a great influence on the natural environment and local communities, we are implementing it based on a development plan that has considered the ecosystem and aquatic environment. At mines overseas currently under development, from the exploration stage we are conducting regular and appropriate environmental monitoring of the ecosystem and water quality. We check to make sure that our initiatives are minimizing the impact on the environment.

Consideration for Biodiversity in Procurement

Supplying paper, a forest resource, is one of the important ecosystem services, and it is also related to climate change and waste. Because the DOWA Group's manufacturing business is mainly in the area of nonferrous metals, we do not use biological resources for our main raw materials, excluding water, but we use paper at all our business sites both in Japan and overseas, and our whole group purchases a lot of paper every year. For this reason, we use paper that is a mixture of used paper and forest certified wood pulp for copy paper and pamphlets, and we are working to use sustainable biological resources. When we put out a tender for centralized purchasing of paper, we confirm that the paper supplier is a company that “procures paper responsibly” based on our CSR procurement policy.

We also ask that suppliers disclose their environmental activities, such as nature conservation or reducing environmental impact, and we check the status of their efforts through questionnaires and CSR inspections.

Points to be Checked for

“Responsible Paper Procurement”

- Establish procurement policies for wood feedstock.

- Build and operate a management system to confirm the legitimacy of the wood feedstock.

- Provide information on the suppliers of raw material pulp.

Planting Forests in Kosaka, Akita Prefecture

In Kosaka, which lost a lot of forest due to the impact of exhaust gas and deforestation by the mining and smelting industry since the Meiji era, forestation progress has been made with the planting of black locust and Japanese cedar trees after WWII. However, while the black locust trees are highly fertile, they are a species of tree with a relatively short life span, and they are shifting to a period of decline in the growth cycle. The DOWA Group started planting trees in 2006. We aim to create a natural and stable forest so that, different from an artificial forest, it does not require maintenance by human hands. We have worked to restore the original vegetation of the area by “making a local forest with local trees”.

Under the guidance of the Japanese Center for International Studies in Ecology, over the past 12 years we have completed planting about 25 species and 170,000 trees. The seedlings planted in the first year have grown a lot, and now form a small forest.

04Conservation of the Aquatic Environment

Every year at the DOWA Group, in addition to knowing the amount of water used at production bases in Japan and overseas, we understand the situation for the water intake sources and where the drainage goes. We are working to reduce the amount of water used by the entire group, and we promote efficient use within our facilities to reduce the amount of water intake.

Water Resources

In FY 2016, the water resource input was 82.4 million ㎥, which was down 10% from the previous year mainly due to the reduction of cooling water used in smelting plants. About 83% of the total water resource input was seawater used for cooling water in facilities, such as for smelting, and the amount of fresh water used was 14.1 million ㎥, around the same level as the previous year.

In FY 2016, we worked on the conservation of water resources by changing from cooling water to air-cooling for compressors, and by starting to use recycled water.

Drainage Water

In FY 2016, the amount of drainage water was 94 million ㎥, down 10% from the previous year. While this was due to the decrease in the amount of cooling water, the amount of drainage water is decreasing every year. With regards to drainage water, we are striving to control water quality not only by strictly complying with wastewater regulations, but also by establishing strict voluntary standards.

Amount of Water Resources Used

05Promotion of Resource Recycling

At the DOWA Group, together with controlling the consumption of natural resources, we aim to contribute to the formation of a sustainable society by promoting the recycling of used resources.

INPUT

Raw Materials

In FY 2016, the amount of raw materials used was 1,059 thousand tons, up about 3% from the previous year.

Waste Received

In FY 2016, the amount of waste received was 1,629 thousand tons, up about 15% from the previous year. This was due to an increase in the amount of polluted soil received.

OUTPUT

Products

In FY 2016, product shipment volume was 924 thousand tons, up about 46% from the previous year. This is mainly due to the inclusion of sulfuric acid production in the smelting business from this fiscal year.

Discharged Waste

In FY 2016, the volume of waste treatment was 416 thousand tons, down about 3% from the previous year.

Recycling

In FY 2016, the amount of material recycled was 262 thousand tons, up about 16% from the previous year. Within this, the amount that the DOWA Group recycled in-house was 163 thousand tons, and recycling outside of the company was 100 thousand tons. In addition, for thermal recycling, which was down about 11% from the previous year, 93 thousand tons was done by the DOWA Group in-house, and 371 thousand tons was done outside the company.