CSR Initiatives through Business Activities

DOWA Electronics Materials Co., Ltd.

Contribution to Fight against Global Warming

Silver powder and solar cells

Photovoltaic power generation is increasing rapidly by over 40% every year due to rising international awareness of global warming and through the Governmental support. Mono / poly crystalline Si solar cells, which account for 90% of the market, have high conversion efficiency and use silver for their electrodes. Those electrodes use silver powders supplied by DOWA Electronic Materials.

DOWA Hightech

DOWA HightechDOWA Hightech, a manufacturing plant, decided to expand the existing facilities by 150% to respond to ever increasing demand and will start operation in July 2010. As the government of countries all over the world enforces the system to promote solar cells as means to significantly reduce CO2, we have started our system to respond to the demand for 110 tons.

The demand for solar cells is expected to increase further. We are committed to contribute to fighting against global warming via those important materials of solar cells.

Leader's Voice

President Akira Otsuka

DOWA Electronics Materials responds to the market needs by supplying semiconductors, electronic materials and magnetic materials. We aim at being the top company in a wide variety of fields, building on our product families that are backed up by our cutting-edge technologies. We also strive to develop new businesses through active investment. We focus on the development of nitride semiconductors for eco-friendly home electrical and electronic appliances, metal powders for electrodes, in addition to deep UV LED and metal nanoparticles as energy saving parts/ materials in order to contribute to fighting against global warming

DOWA Metaltech Co., Ltd.

Consideration on the Environment and Safety

Development of New High Strength Copper Alloy Products

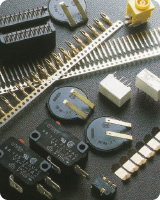

Connectors used for mobile phones and PCs are required to microminiaturized in response to the demand for more compact and lighter appliances. However, the metal materials used for these connectors must have high workability so they can to be made into small but resilient and complicated forms. Although copper containing beryllium has been typically used as material with high springiness and workability, as beryllium oxide is hazardous to human health, alternate materials for connectors have been long sought for.

DOWA Metaltech succeeded in commercializing a super high strength alloy called “YCuT-FX" that has an increased performance added to “YCuT", our copper and titanium alloy that substitute for beryllium and copper alloy, by our proprietary cutting-edge technologies of for texture control and precipitates control. We expect YCuT-FX will replace beryllium and copper alloy due to its performance and lower cost. We are proud of our contribution to building a human- and eco-friendly society from a world of small materials in digital devices for the home.

Leader's Voice

President Hiroyuki Kai

In addition to high strength copper alloy mentioned above, the DOWA Metaltech group has strived to develop, recommend and offer advanced technology in the field of precious metal plating, processing and metal bonded ceramic substrates on a global basis. We would like to continue to contribute to building a clean and rich society in a wide range of application fields by developing new products and services that are eco- and human-friendly and energy saving and by streamlining at the production facilities.

DOWA Thermotech Co., Ltd.

Energy Saving and Improvement of Environmental Performance

Remodeling of Thermal Processing Facilities

Before, we used to keep a pilot burner on all that time to ignite a gas curtain burner, so that the atmosphere inside the furnace is protected when products are put into or taken out of the thermal treatment furnace. As the furnace operates almost 24 hours continuously, annual gas consumption of a pilot burner used to be approximately 1,000m3 and CO2 emission used to be approximately 6.3 tons (from the burning of propane gas).

We thought we could significantly reduce gas consumption and CO2 emission if we could fire up and ignite the pilot burner under a stable condition which can contribute to energy saving and the conservation of the environment. We improved the pilot burner and the flame detecting system, also taking safety aspects into consideration. As a result, we succeeded in not only safety improvement but also reduction of propane gas consumption to approximately 20 m3 and of CO2 emission to approximately 0.12 tons, significant reduction by 98% compared to the time when the pilot burner was always on.

Leader's Voice

President Toshiro Sumida

Realization of low carbon society is a very important theme for us to contribute to society and gain trust from society in order to continue our business. We strive to continue to reduce CO2 emission by implementing energy saving facilities in our thermal treatment and processing plants. We are also committed to developing highly reliable thermal treatment facilities that can contribute to reducing CO2 emission, not to mention energy cost reduction in our industrial furnace business units. Through these activities we would like to play a role in conservation of the environment on our mother earth.

DOWA Eco-System Co., Ltd.

Responding to Diversified Needs

Japan's Largest Waste processing Facility

In October 2009 Eco-System Chiba started a full operation of a plant that can process diverse kinds of waste with both excellent environmental safety and energy savings. The plant also generates power, utilizing waste heat from incineration (power generation capacity of 4,000 kWh).

In October 2009 Eco-System Chiba started a full operation of a plant that can process diverse kinds of waste with both excellent environmental safety and energy savings. The plant also generates power, utilizing waste heat from incineration (power generation capacity of 4,000 kWh).

Recycling of Melted Waste

In December 2009, Meltech joined the DOWA group. Meltech is engaged in manufacturing artificial aggregates used for base of materials made by melting waste ash at 1,800 degrees C.

In December 2009, Meltech joined the DOWA group. Meltech is engaged in manufacturing artificial aggregates used for base of materials made by melting waste ash at 1,800 degrees C.

Verification Test for Hazardous Traces of PCB

We participated in the verification test by the Ministry of Environment of incinerating electric and electronic appliances that contain hazardous traces of PCB. Verification tests were conducted in our subsidiaries of Eco-System Akita and Eco-System Kosaka. We aim at starting in 2010 to process oil from electrical insulators that is contaminated with traces of PCB, leveraging on the certification system of detoxication granted by the Minister of Environment.

First Company in Japan to Obtain a Polluted Soil Remediation Permit

On April 1, 2003, Eco-System Hanaoka and Eco-System Akita obtained a polluted soil remediation permit according to the revised law of preventing soil pollution set forth from the Governor of Akita Prefecture.

The grant of the permit is the result of their accumulated achievements since 2003 when for the first time in Japan both companies were certified to have facilities to remediate polluted soil. They have conducted polluted soil remediation properly and have achieved significant results on soil remediation and also strengthened the standards of environmental management and maintenance of facilities.